In 2006, My family and I relocated to El Paso, Texas. At first I had difficulty finding a job in distribution/fulfillment/e-commerce. In order to support the family, I took a temp job running the receiving department for a company that manufactured server racks in Santa Teresa, New Mexico. I was making minimum wage (a huge pay cut from what my family and I were accustomed), but by paying off bills, and reducing monthly expenses we made it work. By the way, the organization took me on because they had difficulty finding someone with SAP experience–although I did have to convince them that I knew what I was doing. Lucky for me, I started my career in the Dotcoms of the 90s, so I had experience with SAP implementation and staff training.

I enjoyed the job–it was a swing shift position, but I enjoyed the camaraderie of my coworkers. I purchased a 4×4 Chevy Blazer and that made ride home enjoyable. Once my shift was over, I sat behind the driver seat, put on my black cowboy hat, started my car, and drove the dark dessert rode home. I was blasting country music–the only thing on the radio. It turned out to be a nice competition to see who reached El Paso first. I truly enjoyed the drive.

Before starting this job, I applied at various organizations, so I did eventually find a better paying job running HSSE for a manufacturer in downtown El Paso–it was a multi-plant operation.

I was excited to positively contribute to the well being and safety of the organization’s workforce. I was excited to no longer be making minimum wage. I sat in my office in the morning, turned on my computer, poured a cup of coffee then began my morning by walking the main facility. I loved greeting the employees when they reported to work, checking in with the security officers to see what was reported in the log books from the night before.

The company made blue jeans for larger well known brands–like The Gap (this is important later).

I soon found out that the company had had an explosion and fire before I moved to El Paso–luckily, no one was hurt with that explosion. As a consequence OSHA was frequently inspecting the site. also started to realize that the HSSE role was there as a show and was not a role that was truly valued nor supported by the organization. The intent of the company was not to resolve issues nor mitigate possible injuries, but rather to make it difficult for employees who got injured or wanted to discuss deficiencies. Nonetheless, I was determined to make changes and positively impact the organization.

I recall the first time someone got injured I was reproached for documenting it instead of encouraging the employee to just get back to work. I believe the company got away with it’s tactics because it’s workforce was made up mostly of Mexican nationals who legally crossed the border every morning to come to work.

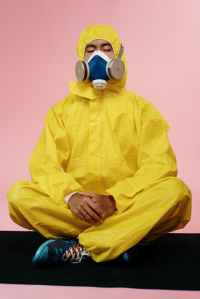

Flammable

As I was leaving to lunch one afternoon, I looked left towards the chemical storage area of the facility. I was already at the main entrance and I continued to walk out and making a mental note to visit the area upon returning from lunch. I stepped outside, but I kept getting a feeling that I truly needed to check that area. I turned around, walked back into the facility, and made my way into the chemical storage area.

When I walked through the plastic curtains that separated the area from the rest of the plant, I saw a maintenance technician getting ready to start a welding torch next to a large chemical container with labels on it identifying the contents as highly flammable and to keep away from flames. He was right next to it.

I informed him that the situation was not safe and that I need him to please move to a safer and more distant spot. He very sternly replied that I was not his boss and that he had a job to do, and that he was going to do it. I showed him the labels and explained the severity of the situation, but he was undeterred. Finally, I explained to him that he may not be concerned for his safety, but that I was concerned for the safety of his colleagues. I asked him to wait until I evacuated the area before he continued. He looked at me, looked at his colleagues who began to leave and reconsidered. He picked up his equipment and went somewhere safer to complete his task.

Wrinkly Jeans

On another day, I was walking the area where they create the distressed or wrinkle look on jeans. The process entailed placing jeans on a mannequin then spraying the jeans with a resin to create the look. The area was a separate enclosed room with many mannequins lined up next to each other with glass walls so that people passing by can look in. I looked in and realized that no one is wearing safety glasses, gloves, respirators, nor safety suits. I am immediately concerned, walk in, and stop production.

I inform the team that they need to wear full suits and gloves to prevent spraying on their skin, that they need to wear respirators so that they do not breathe in the chemical, and that they need to wear safety glasses to protect their eyes. I informed them that they are in close proximity to each other and that they can spray one another by accident. The employees put on the PPE I required, so I move on to another section of the facility.

The next morning I come in, and I am informed that everyone took the PPE off after I left. I am also informed that one of the employees working in that area was sprayed in the eye with resin and he had to be rushed to the emergency room.

Wrinkly Too

On a separate day, I walked into another station where ladies were lined up at ironing stations. Their job is to put jeans on the device, spray resin on the jean, and press a hot iron onto the jeans. As I walk by I notice that they are not wearing, safety glasses, gloves, nor masks. I mention that they should wear them and I begin to listen to complains about how uncomfortable PPE is. As I walk away, I chemist who happens to work at the plant tells me that he is happy to hear what I did. He said he was always concerned that they do not wear appropriate PPE. He continues to tell me that that resin at high temperatures is a carcinogen.

The next day I walk into the same area and no one is wearing their PPE. I speak to the department head who informs me that buying PPE is too costly. He said he’d consider it if the employees can reuse the same gloves and face masks so that his cost does not increase.

24 Hour Shifts

As I was making my rounds one morning, I walked into the area full of sewing machines and saw a group of ladies who I said hello to the day before. i don’t know why I noticed it, but I noticed that they were wearing the same clothes as the day before. I walked over and said hello and asked how they were doing. They replied that they were tired from their long shift. I was a bit surprised because I saw them yesterday and said that they’re sift just started. They told me they had yet to leave and had worked a 24 hour shift. Another lady replied that she was on 26 hours.

I was shocked. I went to their boss and asked it that is possible and he replied that it was true. I then went to HR to find out why we have employees working such long shifts. I mentioned that that cannot be good, and how is that even legal. I was told that no laws were broken. I was also told not to worry because they weren’t going to get overtime pay because they’d only be allowed to work 40 hours. I mentioned that I wasn’t worried about the overtime pay rather their health and well being. How can it be safe for anyone to work 24 to 26 hours sitting behind a sewing machine. Again I was told the company did nothing illegal.

At this point, I knew the practice of having employees work shifts this long was antithetical to everything I learned and was taught about leadership. I had to do something. I went directly to the owners to plea my case, but I was met with the same stance that the organization did nothing wrong. By this point though, I knew the company was acting contrary to clauses within the contract they had with The Gap. The contract clearly prohibited such actions and enumerated the maximum number of hours an employee can work daily and weekly (including overtime). Ultimately, The Gap did not want to be working with sweatshops and expose workers to unsafe conditions. I brought this up to HR and the owners and was told that that is why they have employees carry two timecards–one for regular hours and one for anything beyond the specified number of hours in a day or week. If the company gets audited they just hide the second timecard and as far as the clients know they are always compliant.

Ambivalence

I did what I thought was right. After my appeals failed, I called The Gap and informed them of the work practices along with how they bypass any client audits. I then submitted my resignation effective immediately. I couldn’t help but have mixed feelings about the whole thing as I drove away in my Chevy Blazer. Was there anything else I could have done? Will the employees coming over from Mexico be okay? Oh, and then there is the matter of not having a job.

Lucky for me, I received a call about a job with Canutillo Independent School District.

Leave a comment